Portable Spot Welding Machine for 18650 Batteries – Compact & Efficient DIY Handheld Solution

It was 2 a.m. in his garage-turned-workshop when Mark hit a wall. His custom-built e-bike battery pack—meticulously assembled from salvaged 18650 cells—was nearly complete. But one final step loomed: connecting the cells with nickel strips. He reached for his bulky benchtop welder, plugged it in, and sighed as the cord strained across the workbench. The first spark sent a jolt through the cell—too much heat. A second try warped the strip. Frustration mounted. This wasn’t the seamless build he’d imagined.

For countless DIYers, this scene is all too familiar. Traditional welding setups demand space, power, and patience—often delivering inconsistent results with a high risk of overheating sensitive lithium cells. What if there were a better way? Enter a quiet revolution in energy assembly: the portable spot welding machine for 18650 batteries, a sleek, handheld tool that’s transforming how makers build, repair, and innovate with battery systems.

More Than Just a Mini Welder: Redefining Portable Energy Assembly

This isn’t just a downsized version of an industrial machine—it’s a purpose-built companion for anyone working with lithium-ion battery packs. Designed specifically for 18650 cells, this handheld spot welder delivers targeted energy exactly where it’s needed, eliminating the guesswork and danger of improvised solutions. Unlike clunky desktop units that anchor you to one spot, this compact device liberates your workflow. Whether you're at a workbench, under a car hood, or setting up a solar rig in the field, you’re no longer tied to an outlet or a heavy chassis.

The rise of mobile making has created demand for tools that move with the creator. Engineers, hobbyists, and repair technicians now value agility as much as accuracy. With this portable welder, assembling a battery pack doesn’t require a dedicated lab—just a flat surface and a vision. It empowers tinkerers to iterate quickly, test designs on-site, and bring ideas to life without logistical overhead.

The Power in Your Palm: Three Pillars of High-Efficiency Welding

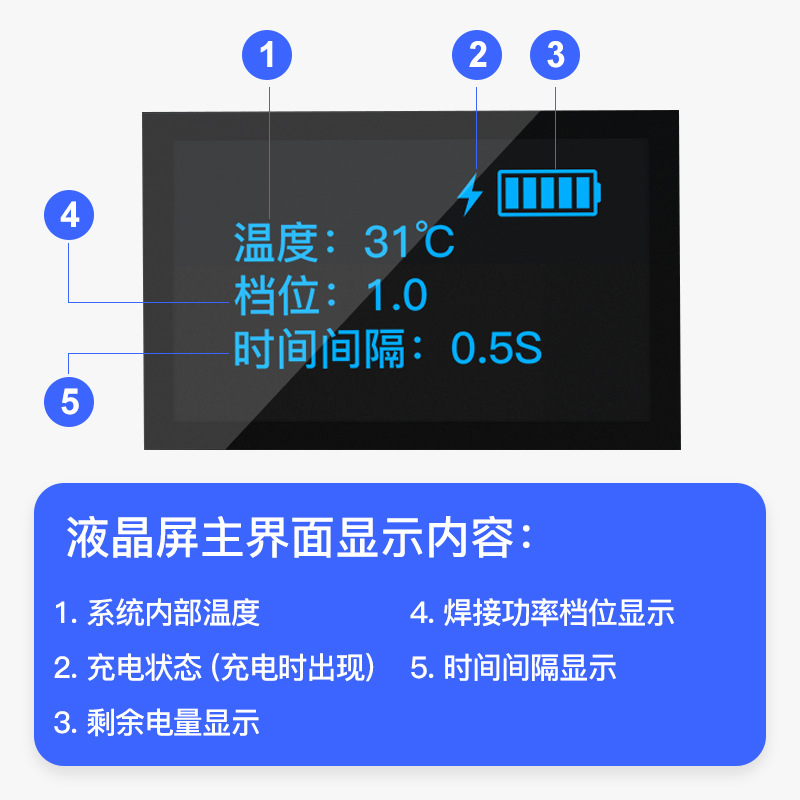

Don’t let its size fool you—this device packs intelligent engineering into every millimeter. At its core is a liquid crystal control panel that puts precision at your fingertips. Adjust pulse duration, pressure, and output level with real-time feedback, ensuring consistent welds across varying cell configurations. No more trial-and-error; each setting is repeatable and optimized for clean, cold-weld results.

How does it achieve such clean joins without damaging cells? Through high-frequency pulsed current technology. By delivering energy in rapid, controlled bursts, the machine minimizes heat diffusion, protecting the internal chemistry of 18650s while creating strong, low-resistance connections. The result? Durable welds with minimal thermal stress—critical for long-term battery health.

Safety isn’t an afterthought. An integrated locking mechanism prevents accidental triggers, while overcurrent and overtemperature protection automatically halt operation if thresholds are exceeded. Every press of the trigger feels confident, knowing the system is watching out for you and your components.

From E-Waste to Empowerment: Ten Stories of Transformation

This tool doesn’t just weld metal—it connects ideas. Consider Sarah, who turned discarded laptop batteries into portable camping power stations for her weekend hikes. Or James, a drone enthusiast who upgraded his quadcopter’s flight time by building a custom 7S2P pack from recycled cells. A technician in rural Kenya uses it to repair solar lighting systems, bringing reliable energy to off-grid homes.

Each story shares a common thread: the ability to create meaningful, functional solutions with limited resources. Whether constructing a wheelchair battery extension, repairing an electric scooter, or prototyping a home energy storage unit, users find surprising versatility in this single device. It scales from beginner projects to advanced builds, proving that impactful innovation often starts small.

Designed to Feel Like an Extension of You

Ergonomics shape experience. The curved handle fits naturally in the hand, balancing weight toward the rear to reduce wrist strain during extended sessions. The electrode tips open wide enough to accommodate multi-layer packs yet remain precise for delicate single-cell touches. And thanks to a modular tip system, swapping between configurations takes seconds—no tools required.

Users consistently describe the sensation as “like holding a pen”—intuitive, responsive, and fatigue-free. When you’re aligning dozens of welds on a dense battery matrix, that subtle comfort becomes indispensable.

The Quiet Choice of Professionals

You might assume portability means compromise—but increasingly, professional repair shops are adopting this handheld welder as their go-to tool. Why? Because speed, consistency, and reliability matter more than footprint. In side-by-side tests, it matches benchtop units in joint strength while consuming less energy and requiring zero warm-up time. Technicians report completing battery rebuilds 30% faster, with fewer reworks due to misfires or burns.

“I used to think handheld meant backup,” says Luis, a certified EV technician. “Now, it’s the first thing I grab. It’s accurate, safe, and goes right into my kit. For field repairs, nothing beats it.”

The Future of Making Is Personal

We’re entering an era where individuals don’t just consume technology—they redesign it. Tools like this portable spot welder democratize access to energy innovation. Imagine classrooms where students build their own solar chargers, or disaster zones where aid workers assemble emergency power banks on-site. These aren’t distant dreams; they’re happening today, one weld at a time.

Perhaps the greatest revolutions aren’t announced with fanfare. They begin quietly—in garages, workshops, and remote villages—where a maker picks up a small tool, feels its balance, and realizes: I can build something that matters.