A sleek, modern design meets precision engineering in every weld.

When Creativity Meets Current: Why Every Battery Artisan Needs a Pocket-Sized Welding Companion

Picture this: it’s past midnight, the city sleeps, but your workshop hums with quiet energy. A row of 18650 lithium cells lines the bench like soldiers awaiting orders. Your fingers wrap around a compact tool—cool metal against skin—and with a gentle press, a flash erupts between nickel strip and battery terminal. Sparks dance, not in chaos, but in controlled brilliance. This isn’t just assembly; it’s alchemy. And at the heart of it all stands a device that’s redefining what’s possible in DIY power systems: the portable spot welding machine.

From weekend tinkerers building their first e-bike battery to seasoned technicians servicing solar storage units, a quiet revolution is underway. No longer confined to bulky stations or dangerous soldering irons, precision welding has gone mobile. The result? Freedom. Flexibility. Mastery over one of the most delicate stages in battery pack construction—all from a tool that fits in your palm.

The Mini Powerhouse: How This “Pocket Titan” Redefines Portable Welding

At first glance, its design speaks volumes. Crafted from lightweight aluminum alloy, the machine balances durability with featherlight portability. The ergonomic grip molds naturally to your hand, reducing fatigue during extended use—essential when you’re assembling hundreds of connections for a custom EV project. But perhaps the most striking feature is the fully rotatable LCD screen, which turns setup into something close to ritual: adjust the angle, fine-tune settings, and lock in parameters with confidence.

Designed to fit comfortably in any workspace—or no workspace at all.

Try placing it in your palm. It barely fills the space. Slide it into a jacket pocket or clip it onto a belt via optional mounting gear. Whether you're under a car, inside a van conversion, or troubleshooting off-grid equipment in a remote cabin, this welder travels where traditional units can't. Inside, silent intelligence hums: an advanced pulse control module works in tandem with an intelligent thermal management system, ensuring consistent output without overheating—even during marathon builds.

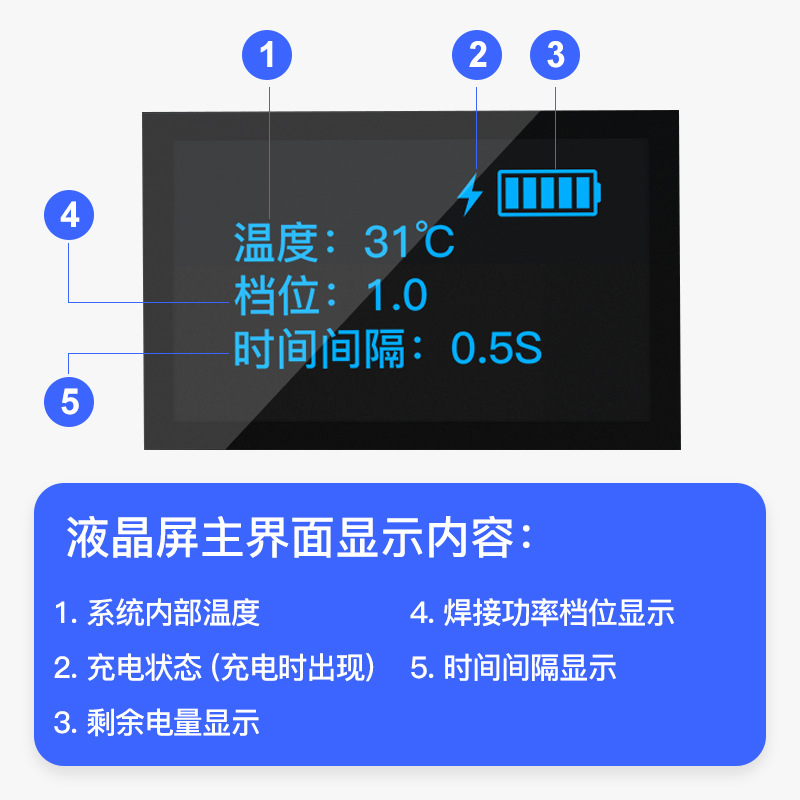

The Eye of Precision: How One Screen Makes All the Difference

In the world of micro-welding, guesswork leads to failure—weak joints, damaged cells, even safety hazards. That’s where the built-in LCD display transforms uncertainty into clarity. Real-time feedback on current intensity, pulse duration, and selected power level turns every weld into a data-driven decision. For beginners, this means avoiding common pitfalls like insufficient fusion or electrode sticking. For veterans, it opens the door to microscopic adjustments that yield flawless conductivity and structural integrity.

Every parameter visible at a glance—precision made personal.

And when the lights go low—be it in a dim garage or outdoors after sunset—the backlight ensures readability without strain. No more squinting, no more errors born of poor visibility. Just clear, confident control.

Built for the 18650: Where Science Meets Craft in Every Spark

Welding lithium-ion cells demands respect. Too much heat damages internal chemistry; too little results in high-resistance joints that compromise performance. Traditional soldering often fails here—it conducts excessive heat directly into the cell, risking leaks or worse. Enter spot welding: localized, instantaneous, and perfectly suited to joining nickel strips to battery terminals without thermal trauma.

This handheld unit excels precisely because it was engineered with 18650s in mind. Precise pressure alignment, optimized discharge curves, and stable contact points ensure clean, repeatable welds across dozens of cells. Users report stronger bonds, lower resistance, and significantly reduced cell failure rates compared to iron-based methods. Whether you’re crafting a high-capacity power bank, upgrading an electric skateboard, or building a modular solar wall, consistency is guaranteed.

More Than Batteries: Hidden Uses You Never Saw Coming

While born for battery packs, its utility ripples outward. Jewelry makers have adopted it for fusing delicate copper wires in artisanal pieces. Model builders use it to assemble tiny metal frameworks in scale aircraft or robotics. In classrooms, STEM educators rely on its safety and simplicity to teach fundamental concepts of electricity and materials science—no open flames, no toxic fumes.

Interchangeable tips enable versatility across projects.

Even fashion tech pioneers are experimenting—embedding conductive threads into textiles, then securing nodes with pinpoint welds that won’t fray or oxidize. The boundaries of application continue to expand, driven by creators who see beyond specs and into possibility.

The Nomadic Workbench: Carrying Your Workshop Wherever You Go

Take Marco, a mobile electronics technician based in Lisbon. He doesn’t own a shop—just a backpack and a mission. With this welder tucked inside, he services electric scooters, repairs drone batteries, and upgrades camper van energy systems across southern Europe. USB-C fast charging means he powers up from any portable battery, and quick-swap electrodes let him switch tasks in seconds. His entire workshop fits in a single bag. He’s not alone. Across continents, independent makers are embracing decentralized production—small tools, big impact.

The Future of the Spark: What Comes When Intelligence Meets Portability?

What if your welder remembered your favorite settings? Or suggested optimal parameters based on material thickness using AI? Imagine Bluetooth connectivity logging each weld for quality assurance, or modular attachments turning it into a multi-function toolkit. As microelectronics advance, so too will these devices—smarter, leaner, more intuitive.

Complete with interchangeable tips and protective case.

Most importantly, tools like this democratize creation. They lower barriers, invite experimentation, and empower anyone with an idea to build something real. So we leave you with a simple question—one that echoes in every spark this machine creates:

Are you ready to hold the next invention in the palm of your hand?