The future of welding fits right in your palm — powerful, precise, and ready to go anywhere.

When Welding Meets Palm-Sized Tech: Redefining the Boundaries of Portable Creation

In today’s maker-driven world, creativity doesn’t wait for ideal conditions. Whether you're building custom battery packs at midnight or repairing a broken tab on a drone frame, the demand for agile, accessible tools has never been higher. Traditional welding setups often fall short—bulky, power-hungry, and confined to workbenches. But imagine this: it's 2 a.m., your workspace is lit by a single desk lamp, and with no extension cords or noisy compressors, you complete a flawless connection between two 18650 cells using nothing but a sleek handheld device. This isn’t science fiction—it’s the new reality of DIY fabrication.

Effortless precision: welding without wires, noise, or constraints.

From Battery Pack to Metal Joint: A Miniature Revolution Built for 18650s

At the heart of this breakthrough lies an intelligent synergy between compact engineering and high-density energy storage. Unlike conventional welders reliant on wall outlets or heavy transformers, this device harnesses the power of standard 18650 lithium-ion batteries—the same cells found in laptops and electric vehicles. These rechargeable powerhouses deliver concentrated bursts of current exactly when needed, enabling clean, controlled welds with minimal heat dispersion. The result? No more tripping breakers or lugging around AC adapters. Simply insert compatible 18650s, secure the terminals, and you’re ready to weld—anytime, anywhere.

What truly sets it apart is its modular energy design. Need longer runtime? Swap in fresh cells or connect multiple units in parallel for extended field use. This approach not only enhances portability but also supports sustainable practices by reusing existing battery stock—no proprietary packs, no e-waste.

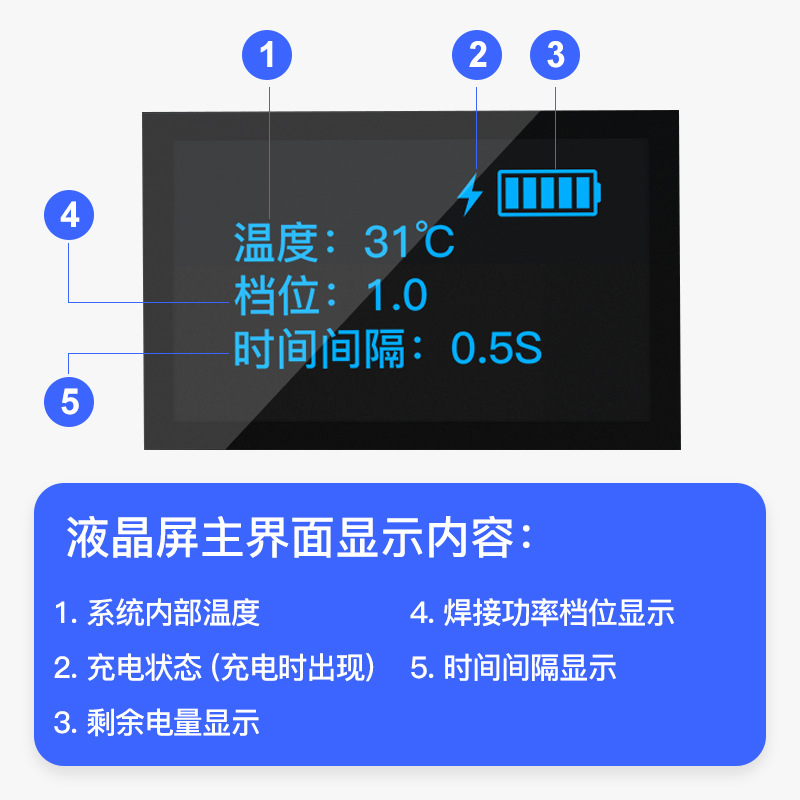

Real-time insights at your fingertips: voltage, charge level, and operation status displayed clearly on the integrated LCD.

Finger-Tip Control, Spark-to-Joint Precision: The Science Behind Touch-Activated Spot Welding

Precision meets simplicity in its touch-based welding mechanism. Activated by gentle pressure, the unit delivers microsecond-level current pulses calibrated for optimal resistance heating at the contact point. Thanks to advanced current regulation, even delicate nickel strips on sensitive battery arrays are joined cleanly—without melting, warping, or damaging adjacent components.

The built-in LCD screen transforms user experience, offering real-time feedback on battery voltage, charge status, and operational readiness. Starting a job becomes intuitive: power on, verify the readout, align the tips, press lightly, and feel the subtle vibration signaling a successful weld. There’s no guesswork, no trial-and-error—just consistent, repeatable results every time.

More Than a Welder—Your Pocket-Sized Mobile Fabrication Station

This tool transcends the workshop. Picture yourself beneath a solar-powered van, fixing a loose terminal on a deep-cycle battery bank mid-road trip. Or imagine a robotics student quickly assembling a competition bot during a campus hackathon, making last-minute adjustments without needing lab access. From model train enthusiasts connecting tiny brass parts to e-bike modifiers upgrading pack configurations, the applications are as diverse as the makers who wield it.

Its compact size unlocks possibilities in tight spaces—inside enclosures, overhead ducts, or narrow chassis—where traditional clamps and cables simply won’t fit. Even outdoor adventurers have found uses, repairing broken tent poles or trailer brackets under the stars. It’s not just about convenience; it’s about empowerment through immediacy.

Engineered for comfort: balanced weight, non-slip grip, and intuitive button placement.

Light as a Marker, Steady as a Vise: The Ergonomics of Intelligent Design

Holding this welder feels natural—its weight evenly distributed, its contours shaped to rest securely in your hand. Textured grips prevent slippage, even during prolonged sessions, while strategically placed ventilation channels manage internal heat without compromising durability. Buttons are recessed to avoid accidental activation yet remain easy to reach. Every detail serves a purpose: reducing fatigue, enhancing control, and ensuring safety during repeated use.

Trusting Every Spark: Where Performance Meets Proven Reliability

Beneath the minimalist exterior lies a robust protection system guarding against overcurrent, short circuits, and thermal overload. Rigorous testing confirms over 300 continuous welds on a full charge (with dual 18650 setup), maintaining consistent contact quality with less than 0.5-second cooldown between operations. Constructed from flame-retardant ABS and reinforced copper alloy tips, each unit undergoes multi-stage inspection before leaving the factory—because reliability isn’t optional, it’s essential.

From beginners to pros, this welder grows with your skills and ambitions.

The Welder That Grows With You: A Companion for Makers at Every Level

For newcomers, the clear interface lowers the barrier to entry—no complex dials or cryptic manuals. Just follow the visual cues and start practicing safely. Seasoned fabricators appreciate its agility, using it for rapid prototyping or field repairs where speed and accuracy matter most. More than a tool, it reignites the joy of making—turning hesitation into action, ideas into reality.

The Future Is in Your Hands: How Portable Welding Is Rewriting the Rules of Making

We’re entering an era where manufacturing isn’t centralized in factories but decentralized across garages, studios, and remote campsites. Tools like this represent a shift toward personal, intelligent, and mobile production systems. As “miniaturization meets smart control” becomes the hallmark of next-gen DIY gear, devices that blend power, precision, and portability will define what’s possible.

You don’t need a garage. You don’t need permission. All you need is an idea—and a spark. Now, that spark fits in your pocket.